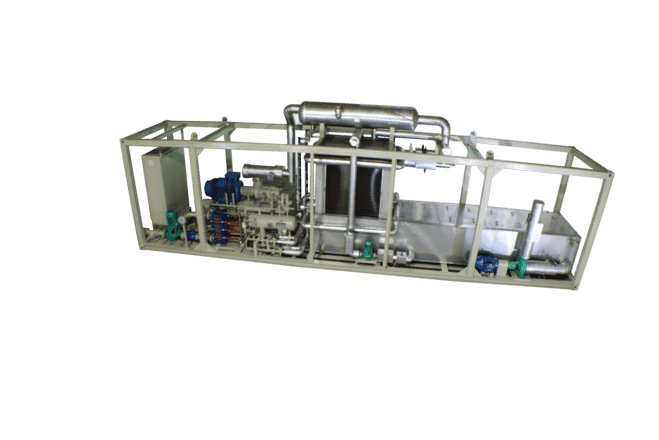

WINTER with its customized packages is able to provide each size of a Thermal Ice Storage for our client’s refrigeration application. We can supply the Thermal Ice Storage Unit alone or as an advanced version, a complete skid mounted Thermal Ice Storage with Screw Compressor and all the other required equipment in order to provide a plug-and-play solution. This will ease the project handling for our clients and will reduce the installation time and cost dramatically. WINTER can provide Thermal Ice Storage with Glycol or Ammonia (NH3) as a refrigerant within the coils or ice bank pillow plates. All of the WINTER packages are designed according to the international standards API, ASME, PED, AD 2000, GOST, etc

Our packages are manufactured and assembled in our own WINTER workshop facilitated with industrial standard equipment, which guarantees the best quality of the client’s package. WINTER closely accompanies its clients, beginning from the first contact and further through the engineering, installation, commissioning, and operation phase.

Thermal Ice Storage

Thermal ice storage is a technology that allows for the storage of thermal energy in the form of ice, which can be used to provide cooling in buildings or other applications. The basic concept behind thermal ice storage is that it is more efficient to produce ice during off-peak hours when energy costs are lower and there is less demand on the electrical grid, and then use the stored ice to meet cooling demands during peak hours.

Thermal ice storage systems typically consist of an ice storage tank, a chiller or other refrigeration system to produce the ice, and controls to manage the operation of the system. During off-peak hours, the chiller produces chilled water that is circulated through a heat exchanger in the ice storage tank. This cools the water and causes it to freeze, forming a layer of ice on the surface of the heat exchanger. The process is repeated until the ice storage tank is fully charged.

During peak hours, the chilled water from the ice storage tank is circulated through the building’s cooling system, providing cooling as needed. As the ice melts, it releases the stored thermal energy, which is used to keep the water temperature constant until all of the ice has melted.

Thermal ice storage has several advantages over traditional cooling systems:

- It allows for the use of off-peak electricity, which is typically less expensive and can help reduce strain on the electrical grid during peak hours.

- It can help reduce the overall energy consumption of a building by shifting cooling demands to off-peak hours, when energy demand is lower and the energy supply is often greener.

- It can provide a more stable and consistent cooling output, as the thermal energy stored in the ice can help buffer against fluctuations in demand or electrical supply.

- It can help reduce the size and operating costs of the chiller system, as the ice storage can serve as a buffer between the chiller and the building’s cooling system.

Thermal ice storage systems can be used in a variety of applications, such as commercial buildings, data centers, and industrial processes. The specific design and configuration of the system will depend on the application and cooling requirements, as well as factors such as available space, energy costs, and environmental considerations.

Advantages

- Reduction of peak daytime power consumption

- Low footprint due to the compact design

- Heavy-duty construction

- Low refrigerant charge

- Lower initial investment due to smaller chiller capacity/size

- The compressor operates at optimum efficiency during ice production

- Less power consumption as the system operates at night with a lower condensing temperature

Applications

- Dairy Industry

- Meat Processing Industry

- District Cooling

- Turbine Inlet Air Cooling

- HVAC