WINTER, as the leading compressor packager in the Middle East, designs and builds packages for process gas applications while using the oil-free compressor technology (oil-free screw compressor and oil-free reciprocating compressor) of the leading European compressor manufacturers. All of the WINTER packages are designed according to the international standards API, ASME, PED, AD 2000, GOST, etc

Our packages are manufactured and assembled in our own WINTER workshop facilitated with industrial standards, which guarantees the best quality of the client’s package. WINTER closely accompanies its clients, beginning from the first contact and further through the engineering, installation, commissioning, and operation phase. Additionally, for the heat exchanger, the standards TEMA and API are taken into consideration as well.

Process Gas Packages

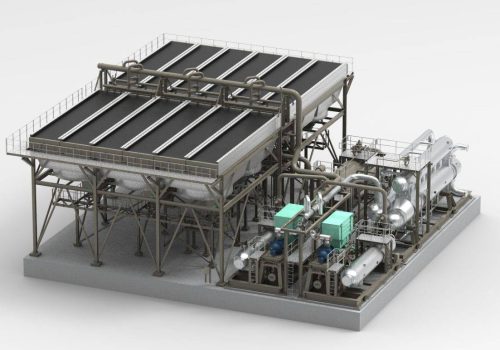

Process Gas Packages are pre-designed, skid-mounted units that are used to treat or condition gas streams in a variety of industrial processes. These packages are designed to meet the specific needs of different applications and industries, such as oil and gas, petrochemical, chemical, and pharmaceuticals.

Refrigeration process gas packages are designed to provide cooling for gas streams in industrial processes. The basic concept behind these packages is to use a refrigeration system to cool the gas stream, which can help to condense or remove moisture and other impurities and improve the efficiency and reliability of the process.

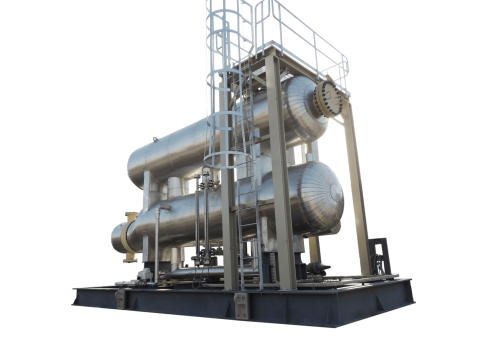

Refrigeration process gas packages typically consist of a compressor, a refrigerant condenser, an evaporator, and associated piping and controls. The gas stream is fed into the evaporator, where it is cooled by the refrigerant, typically in a counterflow arrangement. The cooled gas stream then passes through a demister or other separation device, which helps to remove any condensed moisture or other impurities, before being discharged from the system.

The refrigerant used in refrigeration process gas packages can vary depending on the application and the operating conditions. Common refrigerants used in these systems include ammonia, propane, and other hydrocarbons, as well as synthetic refrigerants such as HFCs and HCFCs.

Refrigeration process gas packages are used in a variety of industrial applications, such as natural gas processing, petrochemical production, and industrial gas production. The specific design and configuration of the package will depend on factors such as the composition and flow rate of the gas stream, the desired cooling temperature, and the space and environmental constraints of the installation.

Some of the key benefits of using refrigeration process gas packages include:

- Improved process efficiency and reliability: By removing moisture and other impurities from the gas stream, the refrigeration package can help to improve the efficiency and reliability of downstream processes.

- Reduced equipment maintenance: By reducing the amount of moisture and other impurities in the gas stream, the refrigeration package can help to reduce corrosion and other forms of equipment damage, which can help to extend the life of downstream equipment and reduce maintenance costs.

- Compliance with environmental regulations: By using low-global warming potential refrigerants and energy-efficient designs, refrigeration process gas packages can help to reduce greenhouse gas emissions and comply with environmental regulations.The specific components and design of a Process Gas Package depend on the application requirements and gas properties such as flow rate, pressure, temperature, and composition. Some common types of Process Gas Packages include natural gas treatment packages, fuel gas conditioning packages, biogas treatment packages, and nitrogen generation packages.Process Gas Packages offer several advantages over custom-designed gas treatment systems. They are pre-designed and pre-engineered, which reduces the overall cost and lead time for installation. They are also compact and modular, which allows for easy installation, mobility, and scalability. Additionally, Process Gas Packages can be customized to meet specific application requirements while maintaining a consistent design and quality.

Products

- Process Gas Package (LPG Compressor Package etc.)

- API 619 Oil-Injected Screw Compressor Package

- API 619 Oil-Free Screw Compressor Package

- API 618 Oil-Free Reciprocating Compressor Package